Implementing a Complete Digital Laboratory with Automated Laboratory Operations for Hindalco Aditya Coal Mine Testing - Jharsuguda

Implementing a complete Digital Laboratory

Abstract

Hindalco Industries (Hindustan Aluminium Corporation Limited) is Asia's largest integrated producer of aluminium and a leader in both aluminium and downstream value-added products in India. A subsidiary of the Aditya Birla Group, Hindalco is also the world's largest aluminium rolling company. Its operations span across bauxite mining, alumina refining, coal mining, captive power plants, aluminium smelting, rolling, extrusions, and foil production at various locations throughout India.

Hindalco’s management has strategically positioned its facilities near raw material sources while ensuring a strong presence in demand markets, which has helped to improve profit margins. The company believes that the implementation of advanced technology not only reduces costs but also delivers superior, customized products. Through technology upgrades, Hindalco has achieved higher plant utilization, improved efficiency, and increased revenue.

In its pursuit of Industry 4.0 standards, Hindalco is gradually digitizing many of its operations. A key part of this transformation is laboratory digitalization, with Revol Process Solutions Pvt. Ltd. (Revol) selected to implement its flagship product, Revol LIMS (Laboratory Information Management Solution). The goal is to streamline all laboratory operations, from sample receipt to reporting, within a single system that tracks assignments and approvals.

Revol successfully implemented processes such as sample management, workflow automation, instrument integration, reporting, CoA forms, and ERP integration. Hindalco's laboratory managers were keen on a solution that could be easily adopted with minimal user resistance. The successful deployment within the committed timeframe positioned Revol as a preferred provider for laboratory digitization.

The Challenges

Hindalco, a key player in the mining and metal industry and a part of the Aditya Birla Group, operates multiple sites, often in remote areas, where building infrastructure for seamless operations has been a priority. Despite efforts to introduce digitization, the laboratories at these sites struggled with inefficiencies and data silos. Previous attempts to digitize laboratory management through internal solutions and third-party vendors had failed due to scalability issues and the creation of data silos, which hindered visibility and increased costs.

The laboratory management faced several challenges, including errors in sample collection, improper sample identification, tracking issues, and heavy reliance on manual data entry. These issues compounded operational inefficiencies, especially since highly skilled team members were spending unnecessary time on repetitive tasks rather than more complex, value-added work. Additionally, the IT team was concerned about integrating the Revol LIMS with their existing CSCTS Server.

The Solution

Revol Process Solutions Pvt. Ltd. was selected after a thorough evaluation of its ability to provide a suitable solution that could address both current challenges and future needs based on Hindalco’s laboratory practices. Revol LIMS demonstrated its ability to automate processes such as sample registration, code generation, barcode/QR code tracking, task assignments, and automatic data capture from various laboratory instruments. Additionally, it was able to integrate with Hindalco’s legacy information systems and machinery that previously had no connectivity, bringing all laboratory operations online.

With Revol LIMS, Hindalco now handles high volumes of sample registrations, complex analytical data capture, calculations, and document storage with increased confidence and efficiency.

Implementation Process

The project execution team at Revol followed a systematic approach to implementing the solution:

1. Kick-Off Meeting: Hindalco’s project team and Revol’s project management team met to define key personnel, establish a communication plan, and review progress regularly. The necessary data for the LIMS system was identified and shared with Hindalco to create a Data Repository as the foundation for the system.

2. GAP Analysis: Revol conducted a detailed analysis of the information flow for sample management, from the collection of sample data through to reporting and final results. The team identified the features already available in the product, the configurations needed, and the customizations required to meet Hindalco’s specific needs.

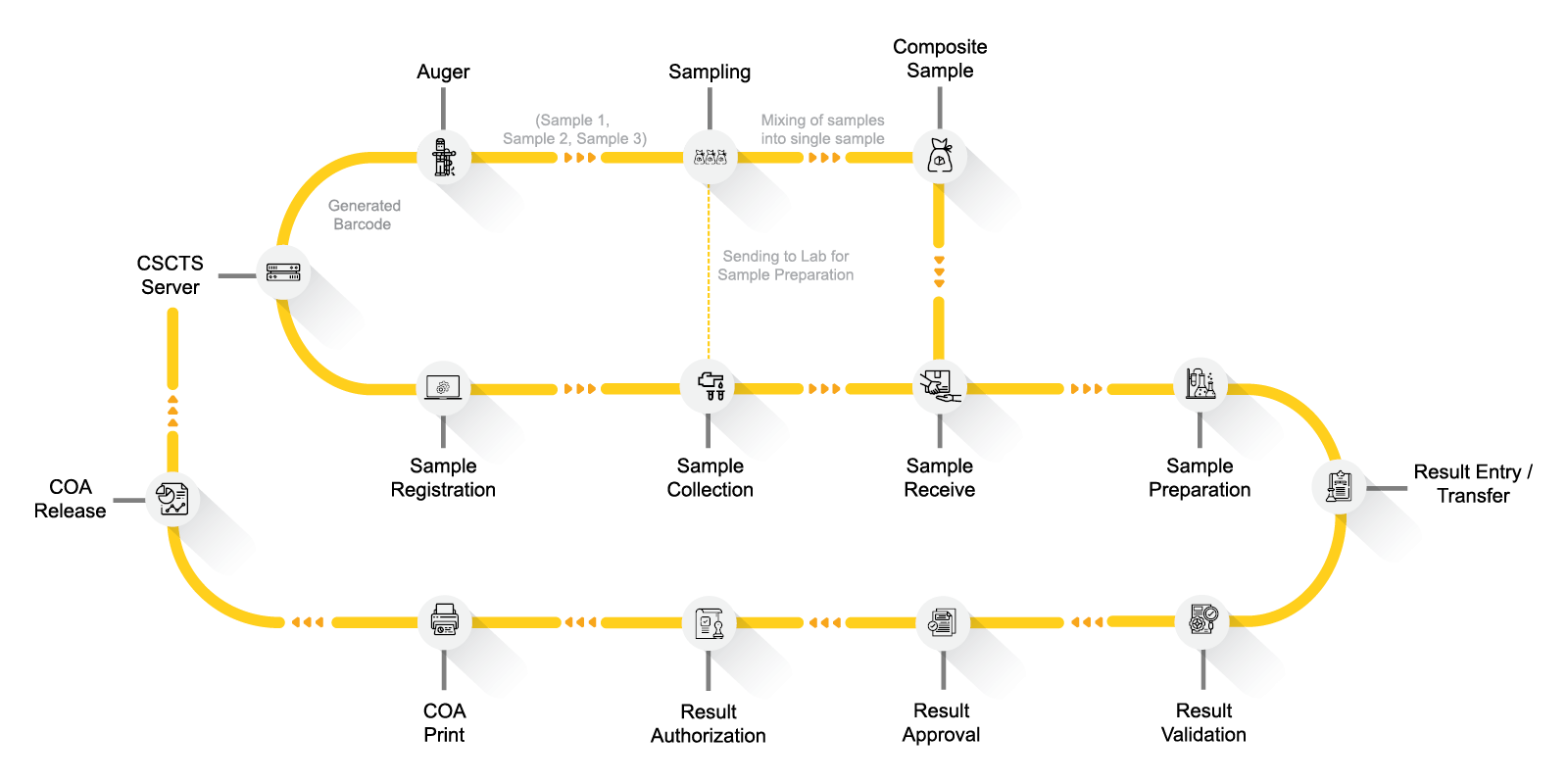

3. Sample Workflow Development: The sample registration process at Hindalco begins at the Auger Mining Machine, controlled by the CSCTS Server, which tracks truck movements from mining sites. It took three weeks for the Revol team to develop and connect the custom plugins to the CSCTS Server, ensuring smooth tracking of sample collection and adherence to Hindalco's standard protocols.

4. Configuration and Customization: Following the insights gained from the GAP Analysis and Workflow study conducted by the Revol team, all required workflows and reports were configured. Where necessary, customizations were developed to meet specific needs. The Revol team set up the sample management module within Revol LIMS, integrating it with the CSCTS Server via the Revol API. This included barcode labeling for samples, instrument integrations, QMS workflow generation, and CoA report creation. Additionally, the team designed and deployed all the necessary reporting templates.

5. Instrument Integration: As part of the project, Revol was tasked with integrating several Analytical Instruments (such as the Bomb Calorimeter, Sulphur Analyzer, and TGA) into the LIMS platform. After gathering file formats and relevant information, Revol’s team developed file parsing protocols to automatically extract data from the reports generated by these instruments. This automation eliminated the need for manual data entry, reducing the risk of transcription errors while preparing reports.

6. Verification and Final Acceptance Testing: The Revol team played an active role in the testing phase, working closely with Hindalco’s team to fine-tune the system design and ensure its compatibility with Hindalco’s network and requirements. Before final deployment, the implementation underwent rigorous testing by Hindalco’s project management team, who verified that the system met the project's initial goals. The LIMS trainers and laboratory staff also reviewed the system’s features and functions, using a checklist to confirm that all components were properly installed and functioning as expected. The goal of this phase was to validate the system’s performance and functionality.

7. Training and Development: The final rollout was supported by Hindalco’s IT team, ensuring any unforeseen issues were promptly addressed. Once the User Acceptance Testing (UAT) was completed and approved by the Hindalco project team, Revol organized and delivered training to the remaining users at the Hindalco site. As the end users transitioned from manual processes to Revol LIMS, they began to familiarize themselves with the system. By the end of March 2021, the Hindalco evaluation team at the Jharsuguda site successfully completed the final acceptance testing phase and signed off on the LIMS implementation project.

The Results

The digitalization of sample registration and data entry has significantly streamlined the laboratory’s operations, allowing for more efficient sample management on a daily basis and providing greater information visibility at various levels of the organization.

Revol LIMS has reduced costs and improved data accuracy through better information management, minimizing errors and the need for manual data entry. It has also helped eliminate data silos, promoting smoother data flow within the organization. Additionally, the solution supports audit requirements by enforcing control over generated results through role-based access and built-in checks. By connecting laboratories across the organization, Revol LIMS enhances visibility and business intelligence, further improving decision-making capabilities at the enterprise level.