Revol LIMS Implementation at HINDALCO’s Renukoot Plant

Implementation at HINDALCO’s Renukoot Plant

Abstract

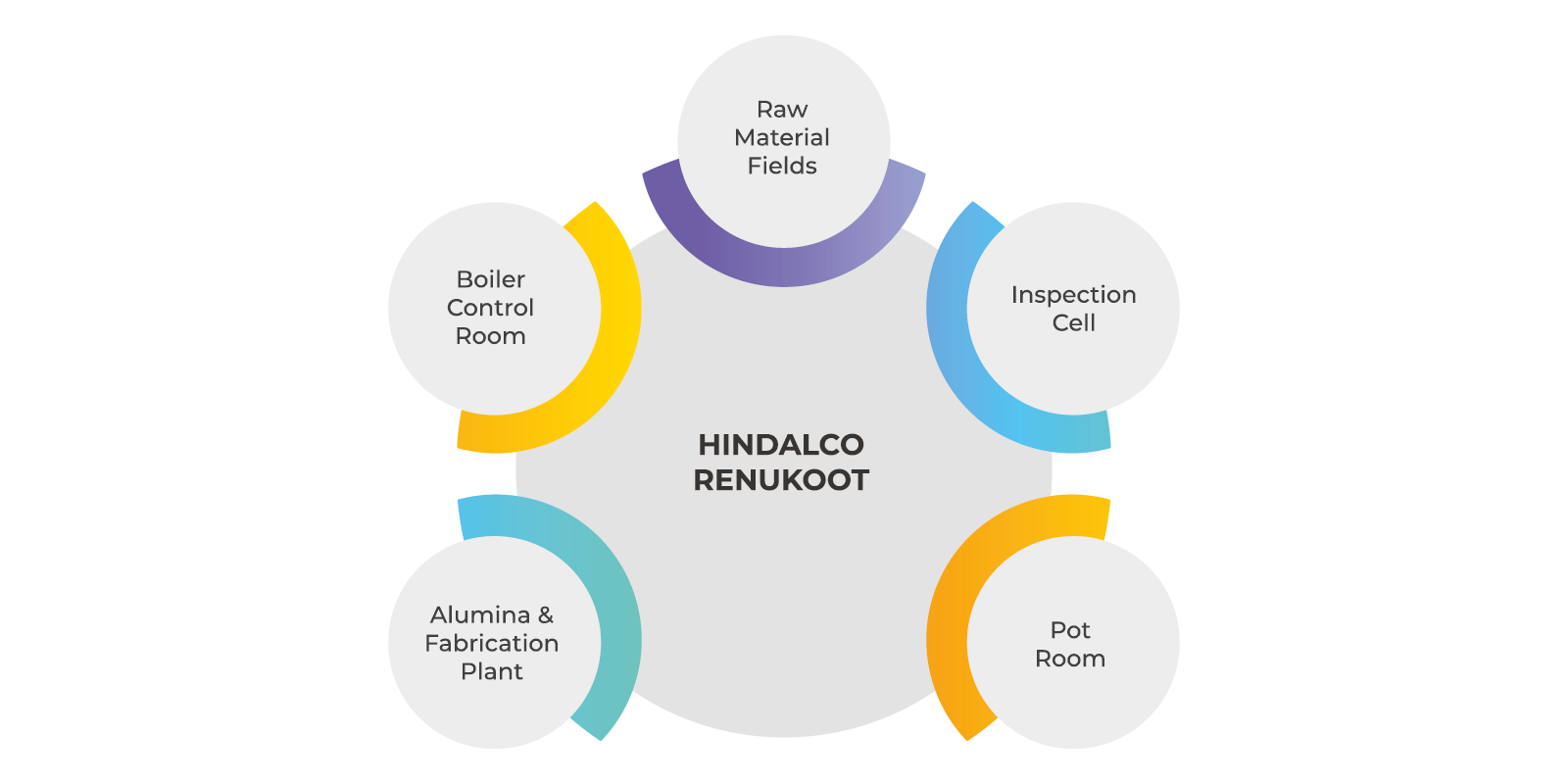

Hindalco’s Renukoot plant was established in 1962 with a single plotline and a smelter with a capacity of 20,000 tpa. Over the years, the plant has significantly expanded its capacity through various brownfield projects and efficient asset management.

Today, Hindalco's Renukoot plant operates with a smelting capacity of 410,000 tpa and covers the entire aluminum value chain, including bauxite mining, alumina refining, aluminum smelting, and downstream rolling and extrusion processes. The integrated facility includes an alumina refinery and smelter, as well as production capabilities for semi-fabricated products such as conductor redraw rods, sheets, and extrusions.

Renukoot has earned the Integrated Management System (IMS) certification, which combines quality, environmental, and occupational health and safety standards into a comprehensive business excellence framework. The unit has also received numerous national and international awards for its achievements in quality, environmental management, and energy conservation.

Business and Operational Challenges

Hindalco aimed to automate and optimize their workflows, particularly to streamline their complex sample management processes. Some of the key challenges faced by the company included:

- Assigning role-based access rights to staff

- Efficiently managing all types of samples and their associated metadata.

- Easily tracking and locating stored samples within their repository

- Generating detailed and customized storage and sample reports

- Managing the shipment of incoming and outgoing samples

- Handling customer information and linking samples to customer records

- Automatically scheduling sample activities

- Ensuring the security of sample data beyond the controlled network

- Pre-planning sampling activities

- Generating plant-specific customized reports based on requirements

The Solution

To address these challenges, Hindalco decided to invest in a Laboratory Information Management System (LIMS) that is lightweight and easy to adopt.

- Ensures data integrity and reduces redundancies across multiple systems

- Facilitates data transfer within the laboratory and supports information sharing across the enterprise

- Increases productivity through efficient management of analytical data and resource planning

- Enhances overall competitiveness by improving collaboration and information management

- Improves error handling

- Provides better control over task workflows and much more

The LIMS Implementation Process

The implementation of LIMS follows four key steps:

- Data Population: Laboratory data and required fields can be populated into the system in two main ways. Users can manually enter the data, though this can be a time-consuming process. Alternatively, with the LIMS solution, users provide master data to the system administrators, who use pre-configured templates to quickly and easily populate the required fields.

- Training: All staff members must be trained to use the LIMS effectively. This training is typically conducted through self-paced guides and reference materials, focusing on the functions most relevant to their day-to-day responsibilities.

- Validation: Validation is a critical step for any LIMS. Some LIMS solutions require extensive customization and validation before final implementation, which can take additional time and resources. Revol LIMS, however, comes pre-validated and provides administrators with validation packages, which can be accepted based on the lab’s risk tolerance.

- Implementation: Once validation is completed, the LIMS is ready for deployment. Laboratories can begin testing their samples, generating data, and automatically tracking results.

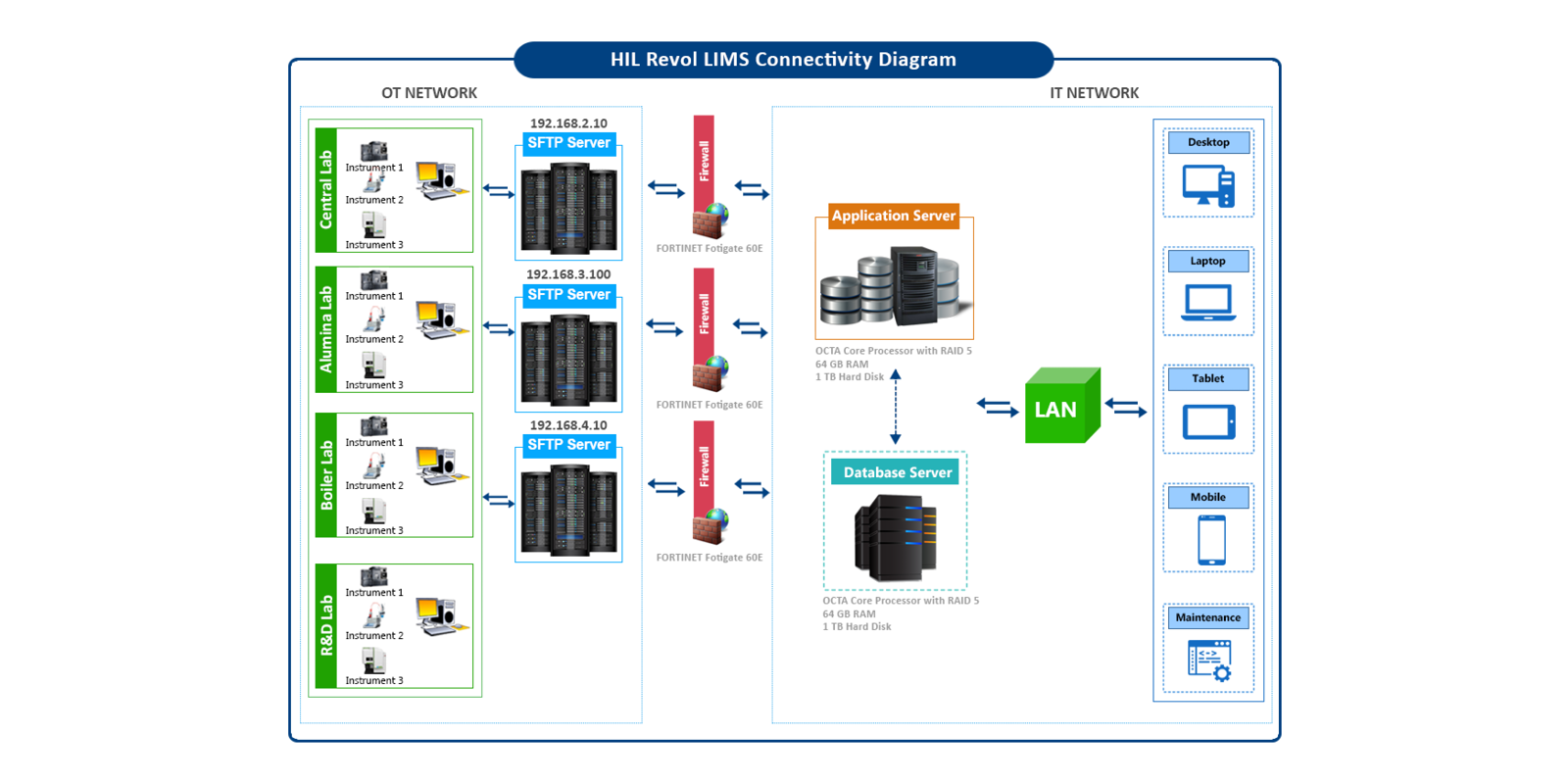

HIL REVOL LIMS Connectivity Diagram

Why Hindalco Chose Revol LIMS

To address their data management and operational challenges, Hindalco (HIL) decided to upgrade their sample management system. The Revol LIMS team preconfigured the system to align with Hindalco's required workflows and demonstrated its capabilities. Ultimately, HIL chose Revol LIMS, a cloud-based solution, to improve their data management and operations. Revol LIMS supported Hindalco through multiple training sessions to expedite the adoption process. Here’s how Revol LIMS benefits Hindalco:

Compliance Management

Revol LIMS supports compliance with ISO 17025.

Role of Revol LIMS in ISO 17025 Compliance:

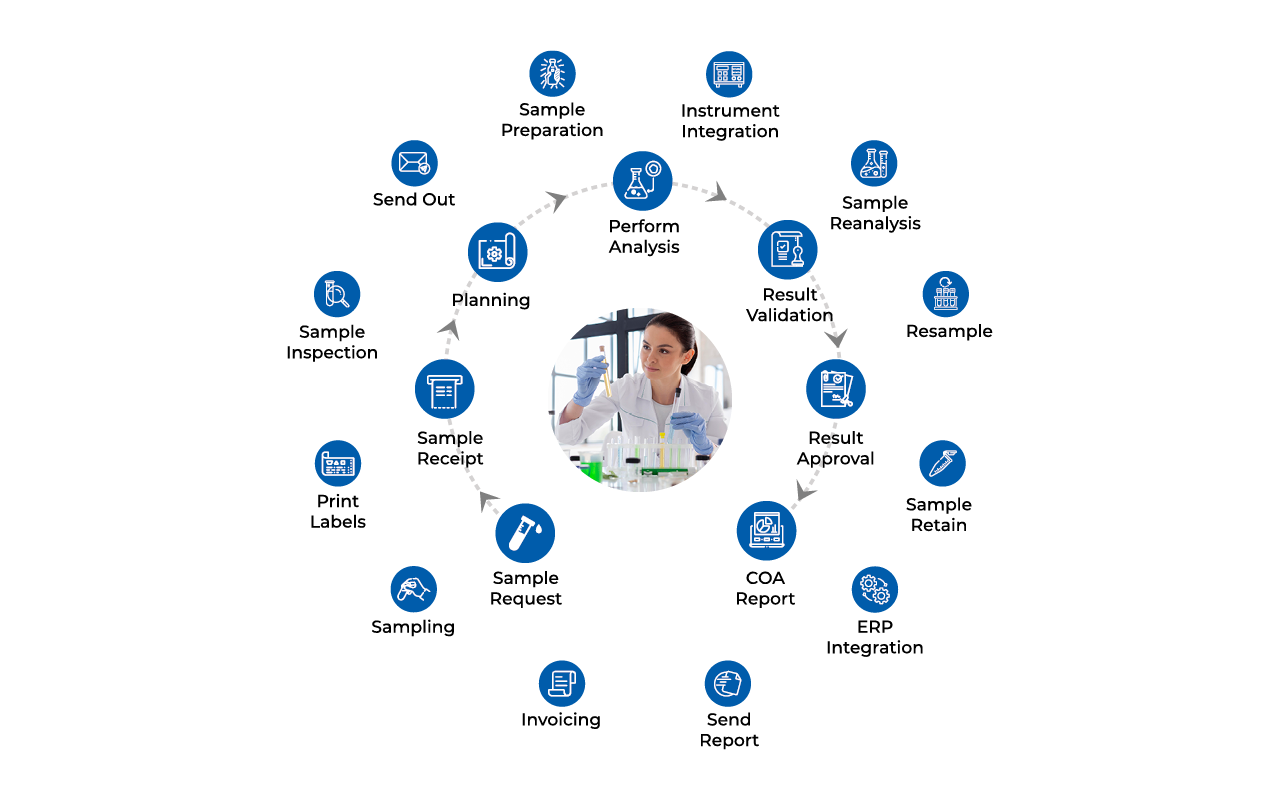

- Sample handling

- Managing and maintaining SOPs (Standard Operating Procedures)

- Managing all test methods and quality-related documents

- Instrument maintenance and calibration

- Quality assurance of test results

- Generating Certificates of Analysis (COAs)

- Conducting data integrity audits

Secure File Transfer

Data and files are transferred securely over a computer network using SFTP and firewalls, ensuring data security in the cloud environment.

Reducing Manual Work and Saving Time

- Reduces paper-based documentation, saving time and supporting more environmentally friendly solutions.

- Sample logging is automated through the Revol LIMS Sample Scheduler.

- Customers can place test requests via a portal, allowing the team to pre-plan sampling activities.

- Integration with 25 instruments means sample results are automatically transferred to LIMS, eliminating manual effort and saving time.

- Hindalco can quickly trace samples anywhere in their repository with just a few clicks, enhancing efficiency.

Role and User-Based Permissions

Revol LIMS allows Hindalco to assign role-based access rights to employees and customers, ensuring confidential data is protected.

Powerful Scheduler Engine

The Revol LIMS Sample Scheduler automatically registers more than 2,000 pre-planned samples on a daily, weekly, monthly, annual, or cyclical basis, streamlining sample management.

Effective Sample Management

- Hindalco efficiently manages customer information and ensures that samples are correctly linked to the respective customers.

- The system mirrors storage inventory using virtual storage units and records customer storage specifications, making it easier to locate samples within storage units.

- Hindalco can manage and track samples more efficiently, capture all necessary data, and generate barcodes.

- The system allows for the registration of up to 2,000 samples and validation of 8,000 to 10,000 parameters per day.

- Hindalco can quickly trace samples stored in their repository with just a few clicks.

Sample Flow

Inventory Management

- Manage stocks

- Reorder thresholds are set for each item and when these are reached an e-mail notification is sent to the appropriate individual for reorder

- Placing Material requests

- Internal Delivery

- Receiving Goods

- Quickly trace samples stored anywhere in their repository in a few clicks, saving time and effort

Instrument Management

- Instrument Data File configuration

- Parameter Instrument Field mapping

- File Result transfer testing

- Sample results will be transferred from instrument to LIMS through instrument integration

Customized Test Reports

- Hindalco is now able to offer more comprehensive and personalized storage and sample reports to its customers

- More complex reports can also be generated with Revol LIMS- Custom Report

- Customer can able to download the reports directly from portal

Benefits Gained by Hindalco

With the installation of Revol LIMS, Hindalco has fully digitalized its laboratory processes. The company is now able to streamline its sample management workflows, adhering to best practices and ensuring high-quality services for their customers. Additionally, data security has been significantly enhanced. Revol LIMS has enabled Hindalco to automate sample logging using the sample scheduler, pre-plan sampling activities, and generate customer-specific reports. This has resulted in faster turnaround times for sample testing. Furthermore, by digitizing processes, paper usage has been reduced, making the operations more eco-friendly.

Revol LIMS has also contributed to a reduction in Hindalco's operational costs.