Laboratory Digitalization at Birla Copper Dahej

Laboratory Digitalization at Birla Copper Dahej

Abstract

Birla Copper Dahej, a division of Hindalco Industries Limited, operates one of the world’s largest single-location custom copper smelters, founded in 1998 in Dahej, Gujarat. Despite its robust infrastructure and ISO certifications, the facility encountered significant hurdles due to manual laboratory methods, leading to inefficiencies, increased workloads, and data management challenges. Recognizing the need for modernization, Birla Copper Dahej took inspiration from successful laboratory digitization initiatives by Revol Process Solutions at other Hindalco locations. After thorough evaluation, they chose to implement Revol LIMS, a 100% web-based Laboratory Information Management System, to transform their operations.

The implementation of Revol LIMS marked a pivotal step towards enhancing data visibility, minimizing manual intervention, boosting productivity, improving traceability, and ensuring safety compliance. The system automated sample management, streamlined repeated analyses, and optimized shift management, significantly reducing employee workload and increasing plant efficiency. Post-installation, Birla Copper Dahej has witnessed remarkable advancements in operational efficiency, industry accreditations, productivity, data security, and quality assurance. Revol LIMS has been instrumental in digitalizing laboratory operations, enabling Birla Copper Dahej to achieve its operational and quality excellence goals, aligning with their vision of sustainable growth and embracing Industry 4.0.

Background:

Situated in the Bharuch district of Gujarat, near Dahej, the complex includes a jetty, refineries, rod plants, captive power plants, and copper smelters. The plant operates continuously and is supported by captive power plants, oxygen plants, and other by-product plants. The facility produces platinum, selenium, silver, and gold at various precious metal recovery facilities and is accredited by OHSAS 18001, ISO 9001, and ISO 14001, and is listed on the London Metal Exchange.

Quality concern is crucial for Birla Copper Dahej, which has set self-imposed environmental targets to ensure sustainability. Copper concentrate, the main component of the copper manufacturing process, is imported via the plant's jetty, operated by Dahej Harbour and Infrastructure Limited, with a capacity to handle four million tonnes of cargo annually. Initially designed to produce 100,000 TPA, the production capacity has increased to meet the growing demand for copper, now reaching 500,000 TPA.

The facility generates more than 800 testing samples daily across 7 labs staffed by 59 lab analysts. Primary products include continuous cast copper rods and copper cathodes,besides gold, silver, phosphoric and sulfuric acid, diammonium phosphate, phospho gypsum, and copper slag. Hindalco is the sole producer of copper rod with a 29.6 mm diameter used for railway electrification in India.

Challenges Faced:

Despite its world-class infrastructure and high-performance metrics, Birla Copper Dahej was hampered by several operational challenges that significantly impacted its efficiency and accuracy. These challenges include:

Manual Data Management: With the facility generating over 800 testing samples daily, manually recording and processing this data became a significant burden, impacting potential productivity gains that had to be achieved.

Manual Data Management: With the facility generating over 800 testing samples daily, manually recording and processing this data became a significant burden, impacting potential productivity gains that had to be achieved.

Traceability of Results: To ensure high quality and market trust, Birla Copper Dahej's import and export operations required precise and traceable reporting. Manual data entry in Excel was both time-consuming and error-prone, leading to inconsistencies and unreliable outcomes.

Traceability of Results: To ensure high quality and market trust, Birla Copper Dahej's import and export operations required precise and traceable reporting. Manual data entry in Excel was both time-consuming and error-prone, leading to inconsistencies and unreliable outcomes.

Instrument Handling: Given the age of operations, Birla Copper's laboratories feature a mix of analog/manual equipment and devices with PC/RS232 connectivity. Manual sample examinations heightened the risk of measurement errors, while managing timely calibrations, scheduling services, and reporting available equipment was complex, ultimately compromising overall quality.

Instrument Handling: Given the age of operations, Birla Copper's laboratories feature a mix of analog/manual equipment and devices with PC/RS232 connectivity. Manual sample examinations heightened the risk of measurement errors, while managing timely calibrations, scheduling services, and reporting available equipment was complex, ultimately compromising overall quality.

Shift Management: Coordinating and managing three shifts presented a formidable challenge. The absence of real-time tracking and oversight escalated employee workloads, reduced efficiency, and hindered operational visibility to the management, impacting operational flow.

Shift Management: Coordinating and managing three shifts presented a formidable challenge. The absence of real-time tracking and oversight escalated employee workloads, reduced efficiency, and hindered operational visibility to the management, impacting operational flow.

Data Access: Accessing generated results manually was labor-intensive and time-consuming, causing workflow disruptions and delaying crucial decision-making processes.

Data Access: Accessing generated results manually was labor-intensive and time-consuming, causing workflow disruptions and delaying crucial decision-making processes.

About REVOL LIMS:

Revol LIMS is a 100% , web-based laboratory information management system specifically tailored to the mining and metals sector, which can be deployed on client servers and accessed across their enterprise. The Mobile Apps allow offline entries from the remote locations with network hassles, these entries are automatically updated once connected to the network.

Process Optimization: Revol LIMS automates and simplifies laboratory workflows, tasks, and resource management. By strategically assigning and optimizing laboratory personnel, tools, and supplies, Revol LIMS enhances data analysis and utilization, leading to more efficient and streamlined operations.

Process Optimization: Revol LIMS automates and simplifies laboratory workflows, tasks, and resource management. By strategically assigning and optimizing laboratory personnel, tools, and supplies, Revol LIMS enhances data analysis and utilization, leading to more efficient and streamlined operations.

Integration Capabilities: Revol LIMS supports seamless data integration with other software systems using protocols such as REST API, etc. This enables efficient data sharing and collaboration across departments, including sales, quality, and production, ensuring a cohesive and integrated approach to operational excellence.

Integration Capabilities: Revol LIMS supports seamless data integration with other software systems using protocols such as REST API, etc. This enables efficient data sharing and collaboration across departments, including sales, quality, and production, ensuring a cohesive and integrated approach to operational excellence.

Traceability: With comprehensive tracking and management of samples from collection to reporting, Revol LIMS ensures controlled movements, conditions, quantities, and storage locations. This significantly enhances overall traceability and accountability, critical for maintaining high standards in laboratory operations.

Traceability: With comprehensive tracking and management of samples from collection to reporting, Revol LIMS ensures controlled movements, conditions, quantities, and storage locations. This significantly enhances overall traceability and accountability, critical for maintaining high standards in laboratory operations.

Operational Excellence: Revol LIMS boosts productivity and plant visibility through comprehensive dashboards and automated workflows. Its real-time monitoring and management capabilities significantly enhance operational control and efficiency, propelling Birla Copper Dahej towards sustainable operational excellence and Industry 4.0.

Operational Excellence: Revol LIMS boosts productivity and plant visibility through comprehensive dashboards and automated workflows. Its real-time monitoring and management capabilities significantly enhance operational control and efficiency, propelling Birla Copper Dahej towards sustainable operational excellence and Industry 4.0.

Solution:

Faced with operational challenges and the need for a more efficient, reliable system to manage laboratory operations, Birla Copper Management embarked on a search for a solution that could fully monitor and systematize their manual processes and automate data visibility across the value chain. They identified Revol LIMS as the ideal choice based on its comprehensive features and rational TCO.

Revol LIMS is a 100% web-based laboratory information management system, which was implemented to fully digitize and manage all laboratory data.

The benefits realized from this implementation included:

Reduced Manual Error: Reduced Manual Error: Automation of data retrieval and processing significantly reduced the likelihood of human errors, saving time and enhancing accuracy.

Reduced Manual Error: Reduced Manual Error: Automation of data retrieval and processing significantly reduced the likelihood of human errors, saving time and enhancing accuracy.

Reporting Transparency: The system simplified the gathering and recording of sample findings, ensuring accurate and reliable results for import and export processes by bringing in traceability from raw material to finished product.

Reporting Transparency: The system simplified the gathering and recording of sample findings, ensuring accurate and reliable results for import and export processes by bringing in traceability from raw material to finished product.

Improved Shift Management: With scheduling and sample workflow management efficiency managing samples and reporting across shifts has become easier.

Improved Shift Management: With scheduling and sample workflow management efficiency managing samples and reporting across shifts has become easier.

Enhanced Quality Management: The comprehensive quality management system provided by Revol LIMS facilitated transparency in operations, traceability in reporting, feedback management implementing CAPA, improved audit preparedness (internal and external) and monitoring proficiency of lab personnel through learning management.

Enhanced Quality Management: The comprehensive quality management system provided by Revol LIMS facilitated transparency in operations, traceability in reporting, feedback management implementing CAPA, improved audit preparedness (internal and external) and monitoring proficiency of lab personnel through learning management.

Impact:

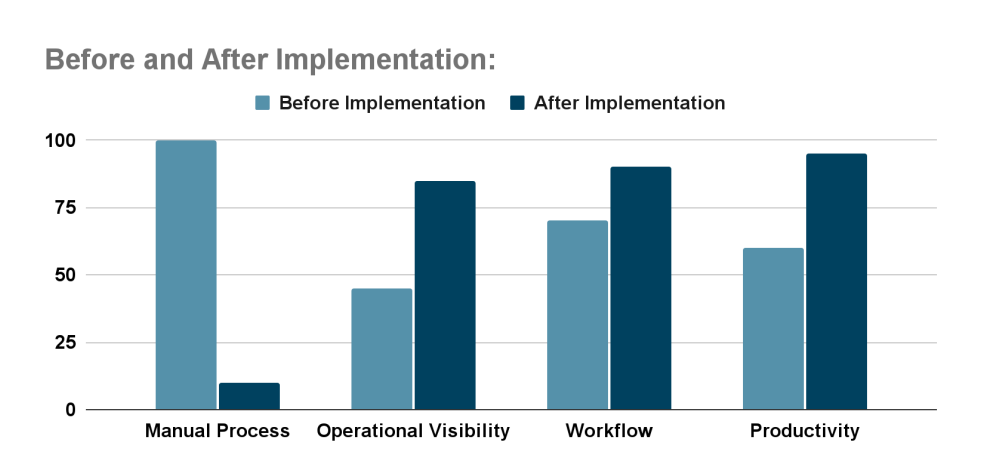

The implementation of Revol LIMS brought about significant improvements in Birla Copper Dahej's operations, including:

The integration of Revol LIMS at Birla Copper Dahej marked a significant leap forward in laboratory operations. Thanks to comprehensive training and support from Revol Process Solutions, the system was swiftly embraced. Revol LIMS effectively curtailed human errors and inefficiencies, elevating accuracy and reliability across lab processes. Automated scheduling and secure data storage not only bolstered management oversight but also amplified operational transparency. This streamlined shift management, reducing employee stress and enhancing workflow efficiency. Through digitized processes and enhanced data accessibility, productivity and operational efficiency experienced a notable upsurge. The rich array of dashboards furnished by Revol LIMS offer real-time insights to management, facilitating astute decision-making and operational mastery. This drives Birla Copper Dahej towards a paradigm of traceable, transparent, and sustainable laboratory operations.

Conclusion:

The implementation of Revol LIMS at Birla Copper Dahej marks a significant leap towards sustainable operational excellence and Industry 4.0 integration. By digitizing laboratory operations, streamlining workflows, and enhancing data visibility, Birla Copper Dahej has not only overcome its operational challenges but has also achieved remarkable improvements in efficiency, productivity, and quality assurance. This transformative step underscores Birla Copper Dahej's commitment to innovation, sustainability, and delivering world-class products. Embracing 100% web-based solutions like Revol LIMS promoted the Birla Copper Dahej facility to continued growth and success in the competitive global market.

Unlock the full potential of your laboratory and operational processes with Revol LIMS. Say goodbye to errors, inefficiencies and excessive workloads. Contact www.revollims.com and embark on your journey towards enhanced efficiency, quality, and operational excellence.